UV Curing

A modern method of CIPP lining, UV curing involves using ultraviolet light to cure the resin. This method offers faster curing times and eliminates the need for water.

Busy life? Believe us, we get it! Malfunctioning sewer drain lines and then dealing with the excavation of trenches associated with them are disruptive. They not only cost you time, but money as well.

The good news is that Wyman can save you time, money and headaches! We are excited about the opportunity of having our certified pipe lining professionals introduce you to the newest in trenchless technology for your home, commercial property or business!

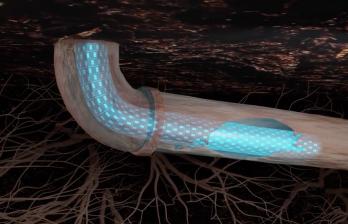

Our most popular trenchless sewer repair services rely on our LightRay LED UltraViolet (UV) Pipe lining system. It is a state-of-the-art cast-in-place pipe technology that ushers trenchless into the twenty-first century. It delivers higher quality results compared to the older traditional thermal heat or ambient curing processes.

Wyman Plumbing & Mechanical is very excited to be an early adopter of this new way to cast emergency pipe liners, which can be deployed rapidly in the field and with no waitlist! It uses non-thermal UV light-activated resins and high-strength flexible fiberglass material in its liners, eliminating hot or cold weather effects while also reducing human errors from mixing resins that cure thermally in previous Cured-in-Place-Pipe lining repair procedures.

The new LightRay Trenchless System is designed to give our certified technicians complete control over an ambient cure lining process.

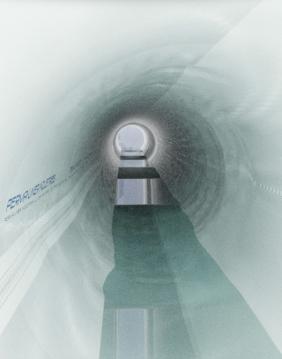

Trenchless pipe lining rehabilitates existing underground pipes without the need for extensive excavation. Here's how our LightRay UV Curing works:

A flexible liner, typically made of resin-saturated felt or fiberglass, is inserted into the existing pipe through access points such as toilet drains or cleanouts.

Once in place, the liner is inflated using air pressure to conform to the inner surface of the pipe. The UV Lights are turned on activating the resins curing process to form a durable, seamless lining.

After the curing process is completed, the repair is considered complete and ready for use!

Trenchless pipe lining is commonly used for repairing cracked, corroded, or deteriorating sewer lines, stormwater drains, and other underground pipes. Here are its common types:

A modern method of CIPP lining, UV curing involves using ultraviolet light to cure the resin. This method offers faster curing times and eliminates the need for water.

LED CIPP is a variation of UV curing that utilizes LED lights instead of traditional UV light sources. It provides similar benefits as UV curing, including faster curing times and waterless curing processes.

Polyester resin is commonly used for CIPP lining and offers cost-effective pipe rehabilitation.

Epoxy resin is a more expensive option compared to polyester resin. However, it provides enhanced durability and strength, making it suitable for demanding applications.

While less common than polyester and epoxy resins, it offers specific advantages in certain situations, such as chemical resistance.

Pipe lining, also known as No-Dig trenchless, is a cutting-edge solution that revolutionizes the traditional methods of replacing underground pipes.

In need of a professional plumbing solution?

We guarantee all of our trenchless pipe lining materials for ten years. Our team is confident that when done correctly, as per the manufacturer’s specifications, pipe lining applications can last 50 – 100 years. We are excited about the opportunity to show you the benefits of pipe lining!